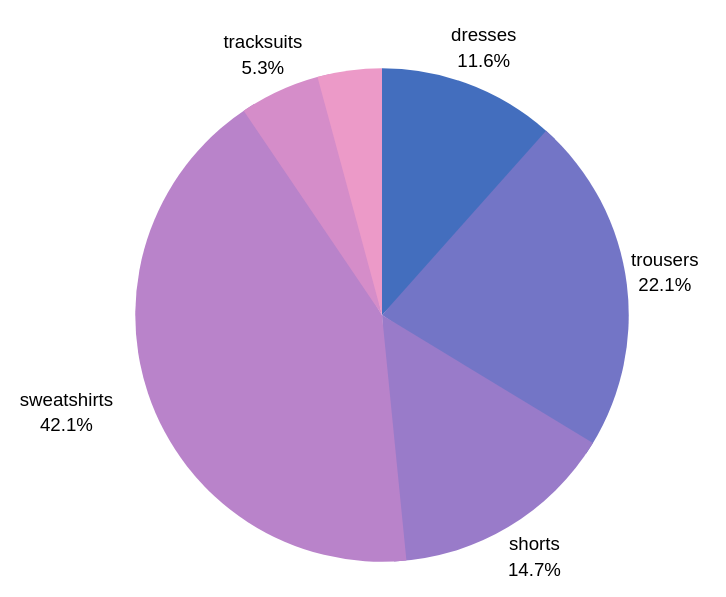

Thousands of second-hand clothing pass through the clothing warehouse every day. Due to a wide variety of styles and colors, it is impossible for manual workers to segregate clothing efficiently. The challenge is to create a segregation system based on variable criteria.

The task can be completed by a set of devices supported by modern video learning machine technology with the trade name fiber.REC. It consists of a perfect quality set of fiber.CAM cameras, connected by a fiber optic cable with a high-class fiber.REC recorder. Its dedicated software uses algorithms to control the recognition of types, shapes and colors. A cooperating advanced interface makes it possible to change the proportions and parameters of segregated clothing.

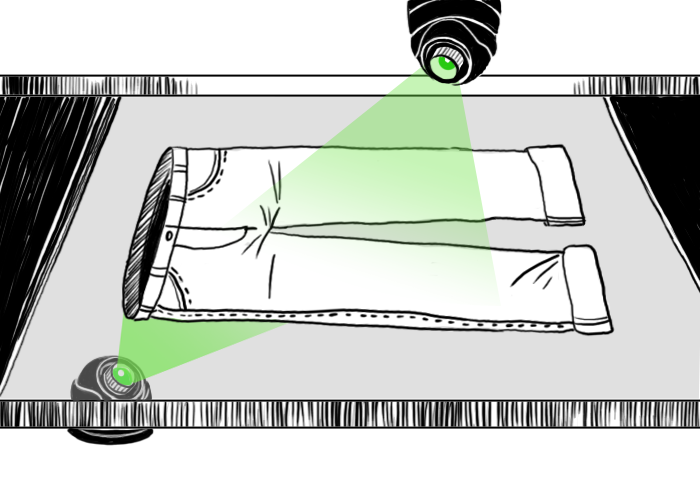

The cameras are placed both above and below a well-lit, transparent table which forms a part of the sorting line. At this point, manual workers only have to separate individual pieces of clothing from each other and place them on the table. The rest is done by our solution. The view from the table is analyzed by the camera instantly and every single piece of clothing is labeled and moved further to one of the tracks from where it reaches a container (depending on the type, size and color). Everything goes smoothly and the cameras placed at different angles collect data much more accurately.

The algorithm is equipped with the detection of garment defects (large holes, stains, etc.), which provides a valuable batch ready to be further processed.

— new level of intelligent security

Train drivers already make use of many facilities which improve their work safety while driving. However, it is a human error which may be the reason of collisions or even railway accidents.

— recognition of situations in need of outside help

A major challenge nowadays is the recognition and prevention of terrorism as well as the management of critical situations (accidents, fires, providing help for passengers). Over 55 billion passengers in the world travel by rail annually.